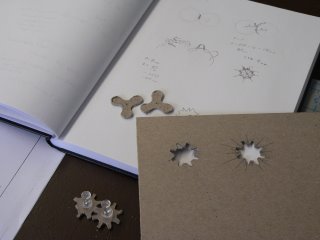

We had some preliminary reviews of our paper machine/drawings in studio. We are now allowed to use bass wood in our designs if needed as we elaborate on our work. I think it is more interesting to continue working just with the paper, so I'm going to avoid using wood for now.

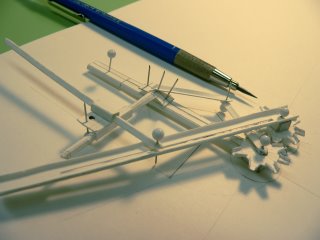

Today I worked on improving my curve-generating machine. I re-layered the parts a bit to improve their function. I rebuilt the 90 degree slider with a larger "foot" so that it wobbles less.

I hope to make the machines operate simultaneously and with a single input of motion. I'd like the drawing mechanism to work autonomously, so I experimented with a few different types of pencils and pens to see how well they draw without using pressure. Pencil hardness's down to 2B didn't mark the paper much at all. Pens were not much better. Conte sticks seem to work well enough that the line becomes visible, so I modified the machine to make it able to hold the Conte stick.

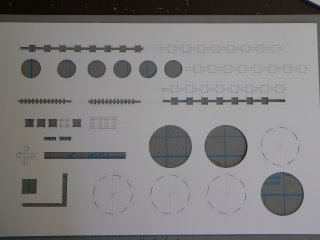

I'm now building some larger pulleys that will be wound with string. Pulling the string will turn the pulleys, activating crankshafts attached to the machines. Or so I hope.